Bosch ME9.6 Repairs or 'Surgical Precision with a Twist'

Even though our repairs have brought many Saab 9-3 II, Opel Vectra C, and Signum vehicles back on the road, there are other engine variants with a similarly challenging fate. The most affected is the version with the 2.8L turbocharged gasoline engine under the engine codes B284E, B284L, B284R, as well as Z28NET, Z28NEL, Z28NER. While these engines are fundamentally robust and offer endless driving pleasure, the control unit is not immune to problems, especially with the aging of the vehicles.

The most commonly encountered error codes for these engines are:

- P0201

- P0202

- P0203

- P0204

- P0205

- U2105 (ABS/ESP error; no communication with the control unit)

U2105/No communikation (ABS/ESP, TCM, ECM)

Let's first focus on this error code. It manifests either during the reading with the Tech2 (mandatory) or through one of the following symptoms:

- The vehicle won't start anymore

- Fuel gauge does not move

In this case, the following components may be in question:

- Transmission control module (TCM)

- ABS/ESP control module

- Engine control module (ECM)

But the question is, how to identify the cause. Below, we will go through each control unit one by one.

Transmission control module (TCM)

If your vehicle does not have an automatic transmission, the TCM is already eliminated. If not, we recommend checking and thoroughly cleaning the contacts of the TCM. Moisture is often found there, but there is no cause for concern, and it can be removed with some brake cleaner and sandpaper.

ABS/ESP control module

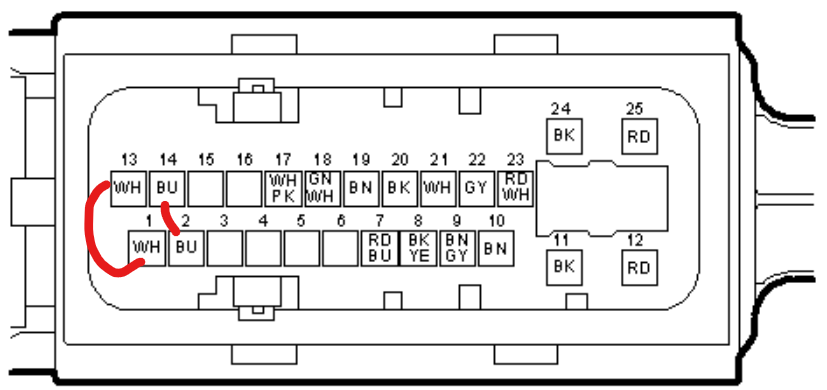

The diagnosis of the ABS/ESP control unit is simpler. You just need to disconnect the plug and insert two wires into the connector as follows:

This bypasses the ABS control unit. If the vehicle starts with this setup, the error is clearly attributed to the ABS/ESP module.

Engine control module (ECM)

From here, it gets complicated, which is why we recommend contacting us. Don't worry, we don't charge a cent for this analysis. However, having some devices on hand for the 'probe' helps, which not everyone possesses.

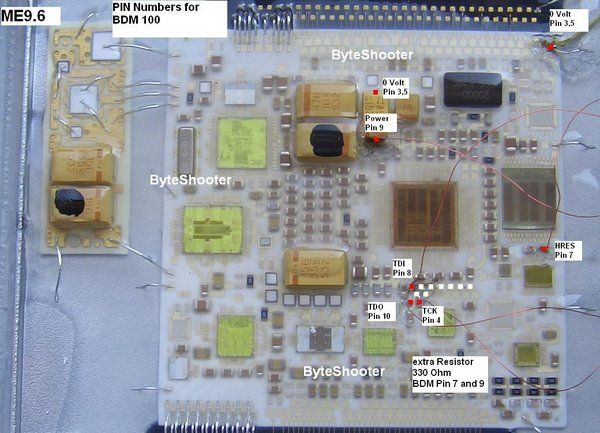

We noticed this when trying to secure the data from such a defective unit. Our special cloning process doesn't work via the CAN bus but uses K-Line in combination with special GPT connections. If the control unit is defective, reading the data is no longer possible. Spatially, the respective connections are located between the two connectors of the control unit. If you heat this intermediate area (also called a bridge) to about 120°C, it suddenly becomes possible to read the data.

During this process, we naturally secure your data and send it to you for free if you wish.

Repairing this error is currently NOT possible, but we are working tirelessly on a solution.

P0201, P0202, P0203, P0204, P0205, P0206

If you have one of these error codes, you can usually relax. For us, it's a standard case, even though the repair methods are anything but standard.

What may have caught the attention of some interested owners is that the Bosch ME9.6 control units seem quite tiny. However, you only truly realize how tiny the control unit is when you open it.

Ultra-thin wires connect the crucial components. Since two different techniques are used here (PCB, which is a solid printed circuit board; wire connections, known as wire bonds), these control units are often referred to as hybrid control units.

However, anyone who thinks that repairing them can be done with a soldering iron and some wire is mistaken. There are three main challenges when dealing with this structure.

- Gel

As can be clearly seen, all components are under a gel-like layer. While it can be easily removed, doing so without it leads to oxidation and additional stress on the connections. Simply putting it back in place is not enough. It needs to be refilled.

2. Wire bonds

The approach with wire and a soldering iron is definitely not far-fetched. We initially tried to repair our first units this way. However, it was not only uneconomical but also short-lived. Reliable bonds require special machines, special wire, and, above all, the right configuration. The work is done at the µm level, so the margin for error is minimal. Too thin, too cold, and the bond won't hold. Too hot, too wide, and the connection is also unusable.

Precision work of this kind requires a steady hand, a lot of expertise, and patience. Assembly line work has no place here.

3. PCB

As you can see, the components are almost unprotected on the circuit board. If they are heated too generously, it will inevitably affect other components. In the worst case, there is a risk of a total loss of the control unit.

Conclusion

If your vehicle does not start, check if the error code U2105 is present (Tech2 required) or if the fuel gauge moves. If yes, go through the control units as follows:

TCM (automatic only) > ABS/ESP > ECM

If there are error codes related to the injectors, the case is often clear, and repair is inevitable.